How To Make Cornhole Boards Slick

Once you've finally put your cornhole lath together or later on you've purchased a cornhole board you'll probably be wondering about applying a cornhole board finish.

But what blazon of terminate should you get and how do y'all apply information technology?

This article will show you some of the all-time cornhole board clear coats (polyurethane and polycrylics) and explain how y'all you should use them.

What is cornhole board terminate?

Cornhole board end is a articulate coat (likewise called a "poly coat" or just "poly") that is applied to your board to protect it from the elements and provide a dainty smooth finish so that your cornhole bags slide across the board.

Get a quality cornhole board set correct now!

Check out my #one recommendation for a quality cornhole board set that is perfect for beginners.

Do you need a clear glaze?

If y'all want your lath to terminal and for your paint job and decals to stay in good shape, y'all'll likely need a clear glaze.

Also, if yous desire your board to exist nice and slick, you'll probably require a clear coat of some type.

Although some play with unfinished boards, almost people I know volition utilize a poly glaze to preserve the quality of their board.

What kind of stop should I become?

In that location are different types of finishes that you tin apply to your cornhole board. I'm going to focus on the two well-nigh popular types of finish.

Polyurethane

1 of the most popular types ispolyurethane.

At that place are different types of polyurethane: oil based and water based.

Oil based solutions take longer to dry and are known for being a more durable product. But oil-based clear coats tend to leave an amber or yellow-tinted coat on the cornhole boards, which can be very unappealing.

Meanwhile, h2o-based solutions dry quicker and exit more of a clear coat on the cornhole boards. If I had to choose one type of polyurethane, I would definitely go with water based.

If you're looking for specific types of polyurethane, I'd recommend:

- Rust-Oleum Wood Intendance Interior Ultimate Polyurethane

- Park'due south Pro Finisher

- Minwax Water Based Oil-Modified Polyurethane

Polycrylic

The other cornhole board finish that is very popular is polycrylic.

Polycrylic is a h2o-based product that'due south ofttimes used when people are going for more of a sleeky/clear advent. Information technology's often used on on lighter wood surfaces, such equally maple and birch and likewise used to cover decals and paint since it unremarkably doesn't get out a yellowish tint.

Information technology dries fast and because it can be a little runny, some people have more trouble applying this finish on larger pieces of piece of furniture.

One slap-up thing about polycrylic is that it'southward often the cheaper option for a clear coat.

Many people find that polycrylic offers a slicker terminate but information technology likewise go become a little sticky at times. If that happens, feel gratis to apply some corn starch on the lath to get things a little slicker.

If you're looking for a specific blazon of polycrylic I'd recommend:

- Minwax Polycrylic

Gloss levels

When shopping for your articulate coat note that at that place will exist different levels of gloss that you can choose from.

For example, y'all might run across semi-gloss, gloss, etc.

I would recommend going with semi-gloss because some of the other levels can be a little too slick. Likewise, sometimes they produce an ultra-shiny sheen, that merely doesn't look at good as the semi-gloss does.

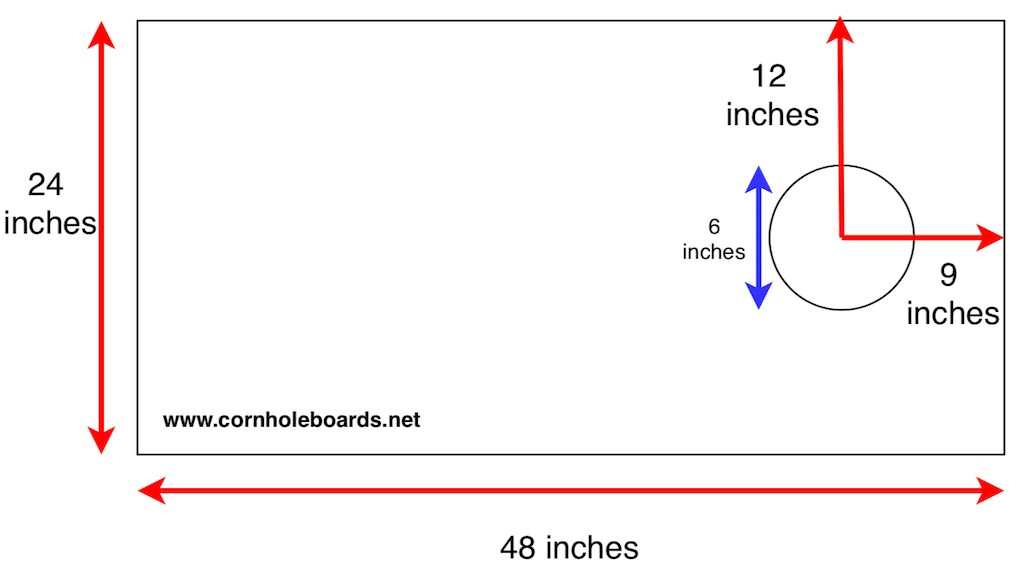

Cornhole board dimensions

Merely in case y'all withal haven't built or purchased your cornhole board yet, you can read here nearly all of the official regulations for cornhole boards.

As well, if you demand to know how to apply your decals, y'all can click here to learn more about that process.

How to apply finish to your cornhole lath

Below are several steps that can aid guide you when applying your cornhole board terminate.

Simply note that at that place'due south not really one single mode to do it then I've provided some unlike methods yous might want to consider trying.

1. Clean your area and comprehend the floor

It's very of import that you first take the time to set up up an area ideal for applying your clear coats. Consider sectioning off a corner of a room or a garage where yous'll take plenty of space.

You desire the area to be make clean and equally dust-free every bit humanly possible.

You can cover the floor with a tarp to protect the flooring.

two. Make clean the cornhole boards

Make sure that your cornhole boards are make clean and grit-free.

If you take pocket-sized specs of dust, clay, or wood on your boards it can touch the application of the clear coat and potentially ruin the cease.

iii. Sanding sealer

A lot of folks like to utilize a couple of coats of sanding sealer.

4. Don't milk shake your poly!

Call back that your finish is not paint and so you lot do not want to shake information technology.

Shaking it will likely consequence in air bubbles which will ruin the application.

5. Employ a cream brush

Some people are tempted to use rolling brushes to apply their cornhole board finish only this is a huge fault. In virtually instances, this will result in air bubbles popping up.

So what you want to do instead is to use a foam brush. This will let y'all to evenly use the poly coat on your boards without the same take chances of air bubbling.

Going with a 3″ inch cream castor is often a good pick merely if your brush is wider you lot tin always but trim it downwards.

vi. Use multiple clear coat layers

You're going to need to apply several layers of poly to your cornhole lath.

If you do enough inquiry, you'll encounter that people vary drastically in how many layers they like to apply. Some stick to effectually five coats while others might do a dozen.

Then there's no true "right" fashion to do it.

Well, except for the fact that y'all want to be as patient as possible and non rush. Focus on applying even coats in a slow, methodical manner and you should be happy with the end results.

For polyurethane, y'all'll probably apply five to 10 coats.

There's a running debate on whether or not you should apply your clear coat over your vinyl decals. Personally, I would practice information technology but y'all've got to consider how your clear coat might consequence the decal downwards the line.

7. Wait for drying

You lot need to be certain to wait plenty of time between coats to allow the poly to sufficiently dry.

Just how long you need to await depends on a lot of factors, such as the type of polyurethane you're using and things like the humidity.

Only by and large, y'all'll desire to expect about 2 hours between coats to be on the safety side. If you tin run your finger beyond the coat and non get any of the poly on your skin, then it might be fix for another layer.

One trick you can do is to use a fan to help the glaze dry much quicker. But y'all need to be careful. That's because if the fan is too potent and the finish is also thin, the fan can blow the finish and crusade it to apply uneven.

For that reason, y'all might want to wait nearly 20 minutes before using a fan to expedite the drying.

Utilize the end to dissimilar parts of the cornhole board

People unremarkably apply coats to the dissimilar parts of the cornhole board. For example, they might utilize x coats to the cornhole lath's playing surface only only use two to three to the legs and sides.

Some people even like to apply clear coats to the within and underside of the cornhole lath to help further protect it from the elements.

8. Sand your clear coats

Many will cull to practise a light sanding when they've applied a hand full of layers (five layers or so) to the cornhole board. Sanding ane of these layers volition ensure that your cornhole lath has better slide.

You want to employ no rougher than a 220 grit sand paper (many utilize an orbital sander with even college grits of 300+) and be certain to do it very lightly.

Then be sure to wipe down your board after y'all sand to remove any small droppings before applying your concluding coat(due south).

9. Let them dry

As excited as you might exist to bust your cornhole lath, the best thing to practice at this point is to allow your boards to dry out completely.

I would recommend waiting 48 to 72 hours for information technology to dry depending on things similar the weather.

Concluding word

Applying your clear coat is all about preparation and patience. If you don't rush through the process and smoothly coat your boards while allowing each layer to dry, yous shouldn't run into a lot of bug.

Source: https://www.cornholeboards.net/cornhole-board-finish/

0 Response to "How To Make Cornhole Boards Slick"

Post a Comment